119. That’s the number of workers killed by combustible dust incidents between 1980 and 2005. Another 718 workers were injured.These alarming stats were revealed by an extensive study conducted by the U.S. Chemical Safety Board (CSB) in 2006. By 2017, another 111 combustible dust incidents had occurred which resulted in an additional 66 fatalities and 337 injuries.

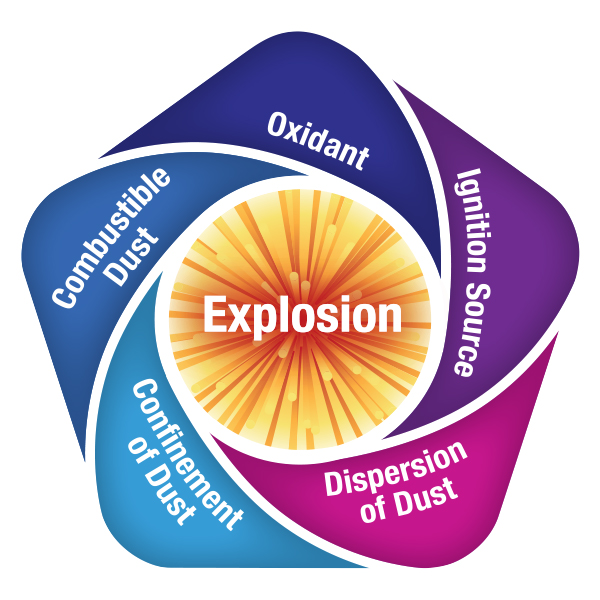

What is the cause of these tragedies? The culprit is combustible dust. Certain conditions generate dust clouds which can lead to deadly explosions. Several components must be present to create these fires.

Recipe for Combustible Dust Event

- An application that generates organic dust (i.e. wood and paper product processing, textile processing, chemical processing). In certain conditions, metals can also generate combustible dust. Over half of the incidents reported in the 2006 CSB study occurred in the food, lumber/wood products, and chemical manufacturing industries.

- A suspended cloud of dust

- Confined conditions to trap the dust cloud

- An oxidant (air)

- An ignition source – This can be a variety of heat sources, including any operation that produces open flames, heat or sparks (cutting, grinding, steaming, welding, soldering, etc.) Even the machinery itself, such as a conveyor belt, can produce a spark that can ignite a combustible dust fire.

Risk Reduction

Aware of this danger, facility operators are looking for solutions that will reduce their risk. Industrial dust fans are proving to be a proactive solution that effectively prevents dust explosions and creates a cleaner, safer, and healthier work environment.

The effectiveness of these industrial dust fans stems from three key factors.

- Control: Industrial dust fans prevent upward thermal currents from holding dust in the air. They create an air barrier that forces the dust particles back to the ground. The resulting air flow prevents the creation of dust clouds that hover above work areas as well as the accumulation of dust on structural supports, pipes, ducts, and process equipment.

Read more about how industrial dust fans work.

- Prevention: By eliminating the combustible dust accumulation, industrial dust fans effectively reduce the risk of fires and explosions. Each dust fan system is custom engineered to provide optimal prevention for their specific environment. Dust fan manufacturers can recommend the ideal location and size of fans for prevention of dust accumulation that can lead to workplace dust explosion incidents. Facility operators can use this custom system to reduce their combustible dust risk to an acceptable level.

- Convenience: Industrial dust fans are designed to make housekeeping simple and safe. Engineered for a specific space, Sonicaire fans are installed to maximize their cleaning power with a minimum number of fans. The fans direct dust downward, where it can be cleaned using regular floor-cleaning methods. Fans can be set to run automatically and can be operated using convenient control panels.

Bonus Safety Benefits

As dust fans reduce the risk of combustible dust events, they provide several additional health and safety benefits to facility owners and their employees:

Regulatory compliance: Due to the threat posed by combustible dust, it is of significant concern for OSHA and NFPA. Companies that do not meet standards set by these organizations face severe penalties. Just last year, a metal tank manufacturer was fined $101,800 for dust accumulation related issues. Industrial dust fans are designed to prevent this accumulation and allow facility operators to comply with government regulations.

Safe housekeeping: Without industrial fans in place, workers must find another way to keep the facility clean. This usually involves accessing hard-to-reach areas, which can be a dangerous task. It may also require operational shut-down while the cleaning is completed. Dust fans accomplish these cleaning chores, so workers do not have to be put at risk. This also results in cost reductions, as workforce resources do not have to be diverted to time-consuming cleaning tasks, and employees can remain productive in other areas.

Improved morale: When employees are surrounded by a clean, safe environment, staff morale is higher. Staff enjoy a better frame of mind, knowing they are working in a clean facility where health risks are low and safety levels are high. This, in turn, can lead to increased production and a healthier bottom line.

SonicAire partners with plant operators to reduce risk and enhance safety. Our proactive dust fan solution is designed to eliminate overhead combustible dust problems. Using proprietary technology, SonicAire industrial dust fans are engineered to effectively eliminate dust accumulations and prevent dust explosions. Our team delivers a customized solution for each facility that maximizes results while minimizing cost. The results are a cleaner plant and a safer employee environment.

To reduce combustible dust risk at your facility, contact the industry leaders at SonicAire for a custom solution and quote.