Insights for Safer, More Productive Manufacturing and Processing

New eBook: Taking the Mystery Out of Combustible Dust Control

Section 1 – What’s the Risk of Combustible Dust?

- Safety

- Productivity

- Compliance

Section 2 – How to Manage Combustible Dust

- Manual Housekeeping – In-House

- Manual Housekeeping – Vendor-Supplied

- Industrial Dust Control Fans

- What About Dust Collection Systems?

What is Combustible Dust?

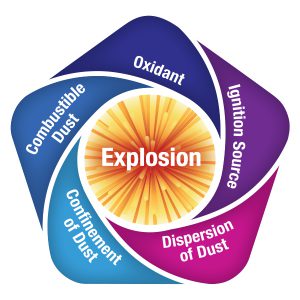

A layer of dust equal to the thickness of a single paper clip can have the capacity to explode, according to OSHA and the NFPA. And according to the annual Combustible Dust Incident Report, there were 194 combustible dust events in the United States in 2018, resulting in 39 injuries and one fatality. A 2018 U.S. Chemical Safety Board (CSB) report recorded a total of 59 fatalities associated with combustible dust incidents over the previous 11 years.

No single sector of industry is responsible for these tragedies. The CSB has reported dust explosions across multiple industries, including lumber, food, plastics, metal, chemical, boat building and electrical manufacturing. Types of dusts include, but are not limited to metal dust, such as aluminum and magnesium; wood dust; plastic or rubber dust; fiber; lint; biosolids; coal dust; organic dust, such as flour, sugar, paper, soap, and dried blood; and dusts from certain textiles. In fact, OSHA has identified over 130 sources of dust that can create the potential for combustible dust events. It’s an issue that is present across the marketplace.

Industry facility managers have responded to the problem of combustible dust with improved housekeeping measures to help mitigate the risk of these disasters occurring. Unfortunately, manual methods and dust collection systems typically aren’t enough to keep up with the accumulation of dust. These manual cleaning methods are also costly and difficult to manage, often requiring shut-downs for manufacturing and significant ongoing maintenance budgets.

How SonicAire Can Help

Fortunately, a better solution for your combustible dust challenges is available. SonicAire’s industrial dust control fans offer a proactive approach. This precision dust-control technology prevents combustible dust accumulation, effectively mitigating the risk of disaster.

The SonicAire Solution

SonicAire proprietary technology combines two methods to control dust flow.

SonicAire fans use high-velocity airflow to clean overhead areas. The strength of this airflow effectively prevents the accumulation of combustible dust particles on overhead structures in the facility.

Typical airflow includes upward thermal currents which naturally lift and carry particles to overhead areas of facilities, where dust quickly accumulates and can become a fire hazard. SonicAire industrial dust control fans prevent these upward thermal currents from holding dust in the air.

Request the eBook

Taking the Mystery Out of Combustible Dust Control

Insights for Safer, More Productive Manufacturing and Processing