The Hazards of Lint in the Textile Industry

What’s inevitable in every textile facility? Lint. These small particles don’t dissipate heat well and offer a high-ratio surface area. The result? Lint particles, and even worse, lint build up. These pose an incredibly high risk of a disastrous fire in facilities that handle textiles.

You’ll see plenty on our site about fugitive dust, but don’t let the word “dust” lead you away from “lint.” When the industry is paper, wood, or even grain, one will likely expect a certain amount of dust management to be necessary, but lint can be just as difficult to manage as dust. – And nearly as dangerous.

You may have seen the “Fire-Building Hack” for creating your own fire starter using dryer lint, and when you consider this, it’s easy to see why you’ll need to put so much stress on eliminating that build up.

The Hazards of Lint in the Textile Industry

What’s inevitable in every textile facility? Lint. These small particles don’t dissipate heat well and offer a high-ratio surface area. The result? Lint particles, and even worse, lint build up. These pose an incredibly high risk of a disastrous fire in facilities that handle textiles.

You’ll see plenty on our site about fugitive dust, but don’t let the word “dust” lead you away from “lint.” When the industry is paper, wood, or even grain, one will likely expect a certain amount of dust management to be necessary, but lint can be just as difficult to manage as dust. – And nearly as dangerous.

You may have seen the “Fire-Building Hack” for creating your own fire starter using dryer lint, and when you consider this, it’s easy to see why you’ll need to put so much stress on eliminating that build up.

Traditional Lint Control in Commercial Laundry Facilities

Fortunately for production and the laundry industry as a whole, smart technology and eco-friendly trends are creating sustainable solutions that conserve more water and energy. That means that a laundry facility’s capacity to operate is limited less by the machines’ operation costs and more by the space they have to safely fill their facility with those high-efficiency machines. Of course, the increase in equipment doesn’t have to mean an increase in the workforce. This fact can save companies tremendously, but it also means there are fewer people to monitor more machines and rafters for lint build up. And if it isn’t being thoroughly monitored, the housekeeping required to manage it is even less likely.

Has your business been doing more with less? Check out 6 Ways to Manage Combustible Dust in a Labor Shortage.

The ducts of each machine, particularly large, industrial machines, must be maintained to prevent fire. When a build up of lint blocks the airflow, the machines and ventilation systems reach incredibly high internal temperatures, and that lint acts as fuel.

Outside of the machines and vents, though, there are still plenty of risks associated with lint. It may not all be combustible, but given an ignition source, it will rapidly spread the fire.

So what is the solution?

Traditional Lint Control in Commercial Laundry Facilities

Fortunately for production and the laundry industry as a whole, smart technology and eco-friendly trends are creating sustainable solutions that conserve more water and energy. That means that a laundry facility’s capacity to operate is limited less by the machines’ operation costs and more by the space they have to safely fill their facility with those high-efficiency machines. Of course, the increase in equipment doesn’t have to mean an increase in the workforce. This fact can save companies tremendously, but it also means there are fewer people to monitor more machines and rafters for lint build up. And if it isn’t being thoroughly monitored, the housekeeping required to manage it is even less likely.

Has your business been doing more with less? Check out 6 Ways to Manage Combustible Dust in a Labor Shortage.

The ducts of each machine, particularly large, industrial machines, must be maintained to prevent fire. When a build up of lint blocks the airflow, the machines and ventilation systems reach incredibly high internal temperatures, and that lint acts as fuel.

Outside of the machines and vents, though, there are still plenty of risks associated with lint. It may not all be combustible, but given an ignition source, it will rapidly spread the fire.

So what is the solution?

Automating Lint Control in a Commercial Laundry Facility

**HLS Linen automates their management of fugitive lint by allowing SonicAire fans to protect their facility from lint build up.

Automating Lint Control in a Commercial Laundry Facility

**HLS Linen automates their management of fugitive lint by allowing SonicAire fans to protect their facility from lint build up.

Automated vs. Manual Lint Control

When it comes to dust and lint control, there are two ways to go about it: Manually or Automatically. The good news is, that automating your lint control isn’t as complicated as you may think.

Check out how in the video below.

What a Facility Needs to Do and What They Should Do

Your facility should conduct a Dust Hazard Analysis (DHA) to see how well it manages dust hazards. Some textile dust can be combustible, but even if that isn’t the case for your facility, commercial laundry and linen service companies inevitably creates lint, which poses a significant fire and pathogen hazard.

Lint is not dust, though. Dust accumulation may have lint particles in it, and vice versa, but the two are not the same. You need to know whether your facility’s housekeeping prevents fire or a combustion event. (A DHA will give you all the details and more.)

You will also need to ensure you’re taking the proper steps to create a safe and compliant environment in your facility. The DHA can give you some tips and recommendations, but if you want to get ahead of any safety requirements, SonicAire can help.

What a Facility Needs to Do and What They Should Do

Your facility should conduct a Dust Hazard Analysis (DHA) to see how well it manages dust hazards. Some textile dust can be combustible, but even if that isn’t the case for your facility, commercial laundry and linen service companies inevitably creates lint, which poses a significant fire and pathogen hazard.

Lint is not dust, though. Dust accumulation may have lint particles in it, and vice versa, but the two are not the same. You need to know whether your facility’s housekeeping prevents fire or a combustion event. (A DHA will give you all the details and more.)

You will also need to ensure you’re taking the proper steps to create a safe and compliant environment in your facility. The DHA can give you some tips and recommendations, but if you want to get ahead of any safety requirements, SonicAire can help.

How Do SonicAire Fans Prevent Lint Buildup?

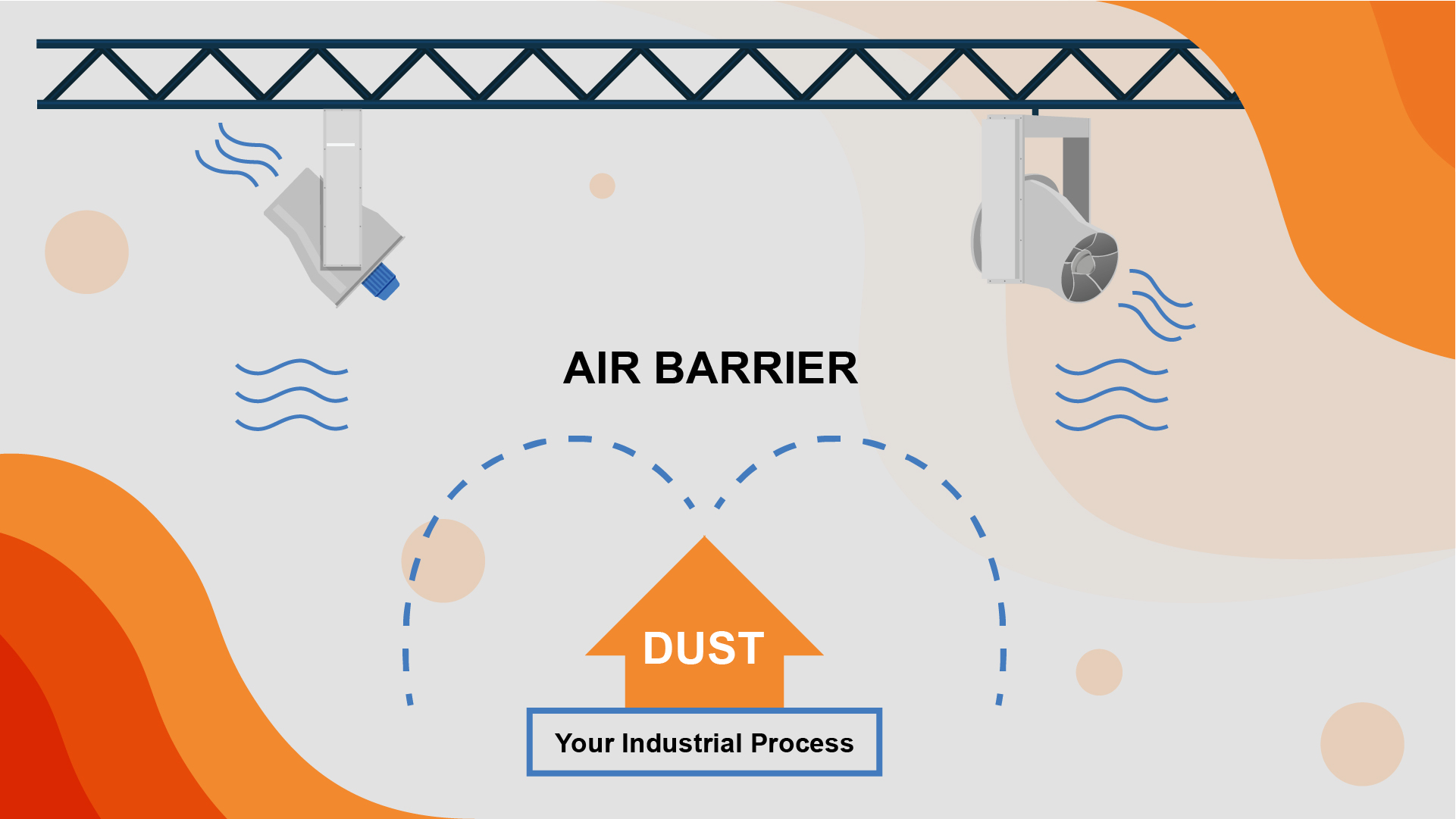

High-Velocity Airflow

SonicAire’s specialized fans use high-velocity airflow to clean overhead areas. This ultra-powerful airflow effectively prevents the accumulation of flammable lint on overhead structures and provides better lint control for commercial laundry facilities.

Thermal-Current Control

Typical airflow involves warm air currents naturally rising and lifting lint to overhead structures where it accumulates quickly. SonicAire’s industrial dust control fans prevent these naturally occurring upward thermal currents from holding lint in the air in the first place. Our fans create an air barrier below the overhead structures, so the lint doesn’t rise above them and then settle on top.

Using these two unique and efficient approaches, and with the help of our specialists, you can be assured that lint accumulation in your facility will be kept at a safe, minimal level.

Contact us today to speak to one of our trained specialists about how SonicAire can mitigate the danger of this lint in your facility. We would love to show you exactly how to make your workspace as safe as possible from dangerous buildup as well as save you time and money from having to do manual clean-up.

What is a Dust Hazard Analysis?

With years of experience in testing and consulting on combustible dust hazards and nearly a century of operations focusing on safety, DEKRA is an excellent all-around resource for your specialized demands.

Click below to watch this conversation and discover the best next steps once you’ve completed your DHA.

Complimentary Dust Management Plan with ROI Analysis

Our analysis will also show you the expected Return on Investment, including equipment investment, estimated annual savings and cumulative cashflow benefit.

Get started by contacting us today for your custom facility review, ROI analysis and fan technology proposal.

Get Your Complimentary Lint Management Plan with ROI Analysis

Our analysis will also show you the expected Return on Investment, including equipment investment, estimated annual savings and cumulative cashflow benefit.

Get started by contacting us today for your custom facility review, ROI analysis and fan technology proposal.