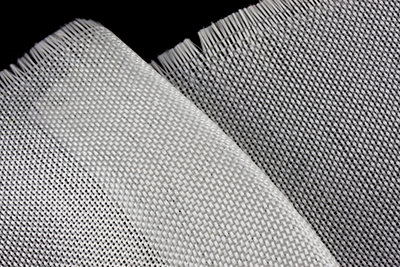

A quick tour through most American homes and neighborhoods will reveal myriad fiberglass products. From boats, to showers, to surfboards and more, the demand for fiberglass molded products continues to grow. In 2018, the U.S. fiberglass market reached a value of $2.1 billion, and demand is expected to reach 3 billion dollars per year by 2024. As a result, products made from fiberglass can be seen in a wide range of markets.

A quick tour through most American homes and neighborhoods will reveal myriad fiberglass products. From boats, to showers, to surfboards and more, the demand for fiberglass molded products continues to grow. In 2018, the U.S. fiberglass market reached a value of $2.1 billion, and demand is expected to reach 3 billion dollars per year by 2024. As a result, products made from fiberglass can be seen in a wide range of markets.

What you don’t see is the incredible amount of dust that was generated when those products were manufactured. The careful shaping and finishing involved require methods that grind, cut, and polish the formed fiberglass products, which release tiny particles of dust. All of that dust was left behind at the factory—and must be managed by the facility owners.

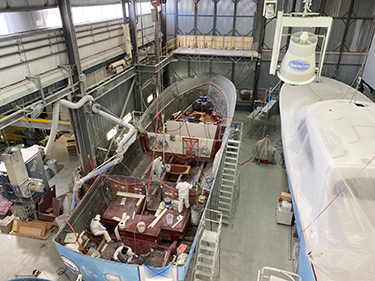

“Sanding SMC (sheet molding compound) products generates dust that transfers up, and above, and everywhere,” notes Tracy Gray, Plant Manager at Continental Structural Plastics.

Jeff Staub, Special Projects Manager for Viking Yachts adds, “Our boats are made from fiberglass reinforced plastic, so a majority of the dust we generate is from sanding and grinding those materials.”

What can managers like Gray and Staub do to keep their work environments clean and safe? Several combustible dust control options are available, but some are more effective than others.

Managing Fiberglass Dust

Staub admits, “When working with these parts, traditional dust collection methods are not always effective and can result in increased housekeeping.”

Gray explains, “A dust collection system can pull the dust away from operators to avoid inhalation, but you’ll still have the housekeeping issue for overhead areas.”

These overhead areas must be properly cleaned and maintained to prevent combustible dust events. If fiberglass dust accumulates, the facility may experience a combustible dust explosion or fire. Just last year, there were 175 fires and 37 explosions across the U.S. related to combustible dust.1

To prevent such incidents, proper dust control measures must be put in place. In fiberglass finishing operations, industrial dust control fans can be an effective option. These fan systems prevent the accumulation of fiberglass dust on overhead areas and eliminate the need for manual housekeeping in these hard-to-reach spaces.

After installing SonicAire industrial dust control fans in their facility, Staub reports, “Using these fans helps keep the housekeeping on the ground where it is easier, cheaper and ultimately safer to clean than high surfaces. With SonicAire fans, it is immediately noticeable that high surfaces—where dust previously accumulated quickly—are clean.”

Dina Graham, Corporate Director of Health & Safety for Continental Structural Plastics, notes, “We saw such a dramatic improvement in dust reduction in the upper levels of the plant that we made the decision at a corporate level to put SonicAire fans in all of our locations.”

How Do Industrial Dust Control Fans Work?

How Do Industrial Dust Control Fans Work?

SonicAire fans apply proprietary BarrierAire™ technology to prevent dust accumulation. This solution combines thermal-current control and high-velocity airflow to control overhead dust. The fans operate continuously to keep dust at ground level and keep overhead areas clean. The system effectively reduces housekeeping costs and maintains safe, compliant conditions.

And each system is custom-engineered for optimal results. Staub notes, “Each target area of our facility has unique characteristics, and SonicAire has addressed those differences in our operations and building designs.”

The Results:

- Reduction in housekeeping costs – Ongoing dust control replaces frequent, costly manual cleanings that may also require shut-downs

- Increased safety – Prevents combustible dust build-up; Eliminates risks of manually cleaning hard-to-reach overhead areas

- OSHA/NFPA compliance – Fans maintain clean surroundings to assist with regulatory compliance and prevent fines and penalties related to combustible dust hazards

The SonicAire Solution

SonicAire fans offer an engineered, robotic solution to control overhead dust and reduce housekeeping costs, while maintaining safe, compliant conditions. Each industrial dust control fan system is customized to meet the needs of individual facilities. Contact SonicAire to receive a personally engineered solution and quote.

How Do Industrial Dust Control Fans Work?

How Do Industrial Dust Control Fans Work?