The Risks and Realities of Grain Dust

The National Grain and Feed Association reports that “grain dust is the main source of fuel for explosions in grain handling facilities.” This dust is highly combustible and can cause fires and explosions if the grain dust accumulates on surfaces or creates dust clouds in the air. Due to this risk, OSHA standards allow a maximum of no more than 1/8 inch of grain dust accumulation in priority housekeeping areas, which include enclosed areas containing grinding equipment or grain dryers, as well as any floor areas within 35 feet of inside bucket elevator legs.

Despite these standards, the grain industry continues to battle combustible dust events. According to OSHA reports, over the past 50 years, grain handling facilities in the United States have experienced over 500 explosions, injuring nearly 700 people and killing 180. In 2023 alone, there were seventeen grain dust explosions.

Nationwide, food products made up 43% of the materials involved in combustible dust fires and explosions in 2023, according to the 2023 Combustible Dust Incident Report. Within the food industry, there were twenty-one combustible dust fires and nine explosions.

Such incidents can be caused by problems such as a hot bearing, overheated motors, misaligned conveyor belts, or even a spark from a bucket elevator. With the significant amount of dust generated by loading and processing grains, it’s a challenge for facilities to keep up with the proper housekeeping measures required to avoid combustible dust events.

From Manual Cleaning to Automated Efficiency

Ron Kirkoff, Regional Operations Manager at Furst-McNess, claims SonicAire made a big difference in their feed mills. Ron oversees multiple locations producing all kinds of animal feeds and shares the struggles of managing dust in these environments—especially in areas with strict safety requirements like Class II, Div 1 & 2 zones.

Before SonicAire, dust control meant a lot of manual cleaning—time-consuming, risky, and expensive. Now, thanks to SonicAire’s automated system, they’ve not only improved safety and kept dust under control but also saved around $10,000 a year in overtime costs. Ron gives props to SonicAire’s team for their attention to detail and recommends their system to anyone dealing with similar cleaning headaches. Watch the video to hear his story!

Introducing the First and Only CII, D1-Certified XZ-210 and XZ-215 Fans

SonicAire’s latest innovation, the CII, D1-certified XZ-210 and XZ-215 fans, are purpose-built for hazardous, highly explosive environments. Class II, Division 1 (CII, D1) environments are areas where combustible dust is always present in sufficient quantities to pose a risk of fire or explosion under normal operating conditions. These locations require specialized equipment designed to prevent ignition sources and ensure safety.

Facilities involved in food production, grain handling, and agricultural processing often meet the criteria for CII, D1 classification due to the presence of fine, combustible dust generated by ingredients like flour, sugar, cornmeal, and other grains. This dust can accumulate on surfaces or remain suspended in the air, creating hazardous conditions if not properly managed.

Engineered to meet these rigorous standards, the XZ-210 and XZ-215 fans deliver unmatched performance in controlling fugitive dust, preventing buildup, and maintaining compliance with NFPA and OSHA regulations. With SonicAire’s advanced design, facilities can enhance safety, protect workers, and operate more efficiently in these challenging environments.

If you’re wondering whether your facility is one of these environments, check out our video below, “How Do I Know if I Have a Class II-Rated Environment?”

Why is Grain Dust So Volatile?

Food products make up roughly half of combustible dust events in 2021. Technology like SonicAire’s dust control fans and better grain handling practices have made incidents less common than in the 1970s, for example, but the hazard remains. But why is grain dust (or sugar or corn) so volatile?

There are 3 measurements that determine combustibility. Do you what they are? Click below to hear from Jordan Newton, SonicAire’s COO, and to see if you’re right.

SonicAire Contributes to a Meaningful Community Project

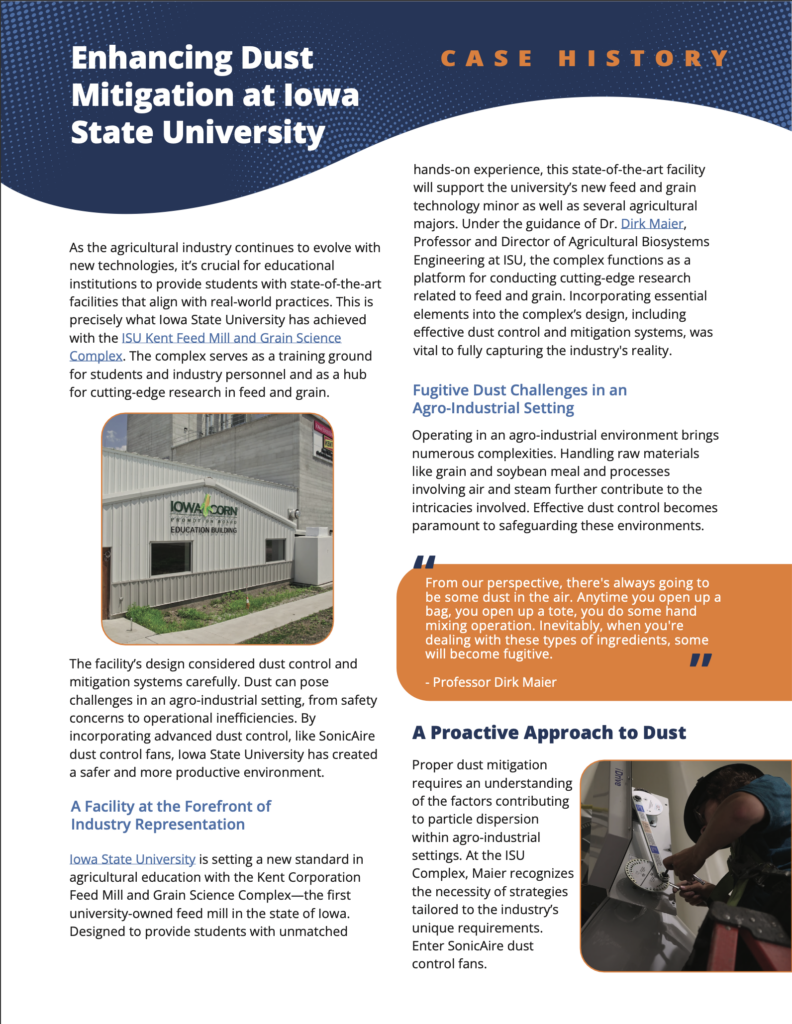

Featured in a recent Feed and Grain article, the Iowa State University Kent Feed Mill and Grain Science Complex is a $30 million facility that aims to cultivate students for careers in grain and feed operations. The facility brings together academia, the commercial grain and feed industry, and their suppliers for a single mission. Funding for the facility came through financial gifts and equipment donations by suppliers nationwide, state and regional grain companies, and feed manufacturers.

The main components of the 47,000-square-foot complex include an ingredient warehouse and education building with a 50-person classroom, analytical laboratory, and pilot plant, a 100-foot concrete mill tower, a 40-foot concrete pelleting plant, and 200,000 bushels of grain storage with handling and drying equipment.

SonicAire believed so thoroughly in this project that we, too, contributed towards its success. We donated three dust control fans and a control panel to ensure the mill had the best grain dust control system.

Successful Dust Control in Plastic Facilities

At The AZEK Company’s Corey Street Plant in Scranton, PA, operations run 24 hours a day, 365 days a year. With continuous blending operations, PVC dust ended up everywhere. The company’s insurer was concerned about the quantity of dust and considered raising rates due to the liability of a combustion event.

Click the video below to hear the case study.

How Can Your Facility Manage Combustible Plastic Dust?

When it comes to fugitive dust, you have a few options. With plastic dust, however, those options depend heavily on safety. You can remove the dust after it accumulates with blow down methods, like pressurized air. Of course, that’s pretty difficult to do safely and requires a strict (and often impossible) set of requirements to be within regulations. (See the National Fire Protection Association’s Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids NFPA 654, section 8.2.2.4 for the details on requirements and whether or not it’s even a possibility for your facility.)

You could also elect to clean the dust after it builds up. This option requires a significant workforce and regular maintenance. You should note you may need to shut down your facility’s production while you perform these cleanings, and pulling employees away from their regular tasks to complete it is commonly met with a drop in employee morale. You could hire an external cleaning crew, but that expense is pretty steep, and you’ll need to pay it frequently.

The final option is prevention. To keep dust from ever accumulating is the one that keeps your facility safe and compliant with dust management every second of every day. There isn’t ever a time when your facility is at risk for a combustible dust event, and a surprise inspection will never catch you with bad dust housekeeping practices.

No one wants a fire, but plastic dust has an added danger level that requires you to maintain constant diligence in preventing dust accumulation. With the possible toxic gasses released in the event of a fire melting the plastic dust, extra care must be taken to prevent fires from ever occurring. This need makes it especially appealing to, rather than clean up the dust regularly, prevent it from ever accumulating.

Dust control fans from SonicAire make the prevention of dust build up easy.

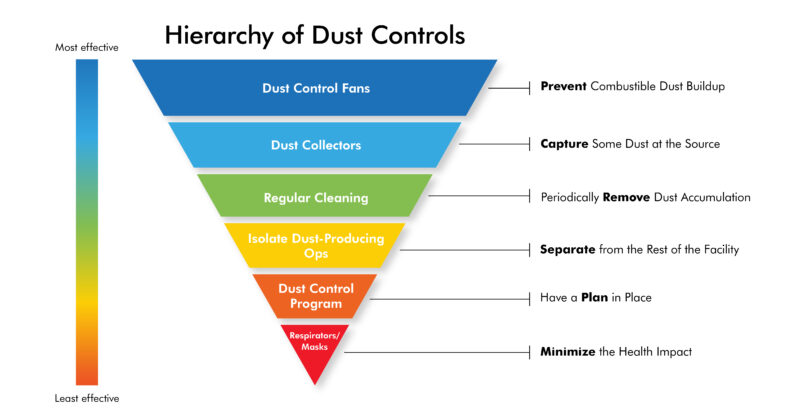

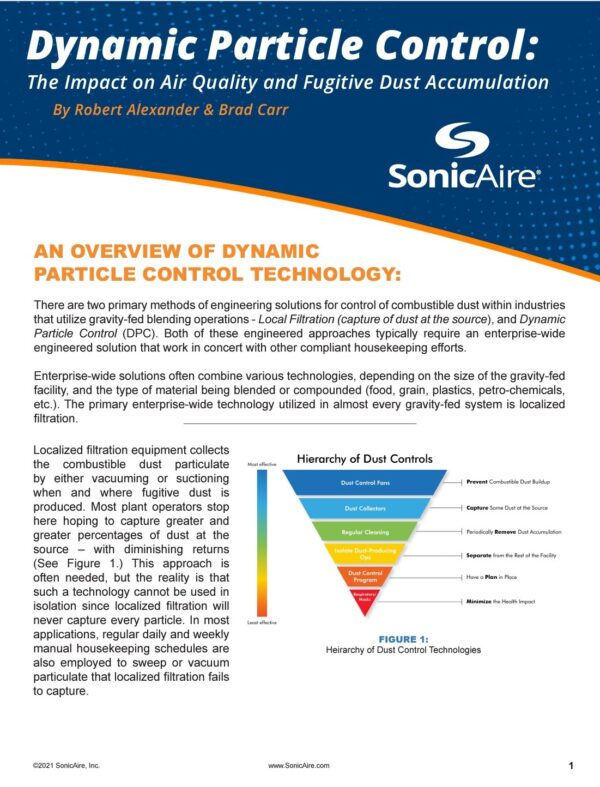

For more on your dust control options’ effectiveness, check out Ranking Six Combustible Dust Control Measures From Least to Most Effective.

How Do SonicAire Fans Prevent Dust Buildup?

SonicAire’s proprietary technology combines two methods to control dust flow.

High-Velocity Airflow

SonicAire’s specialized fans use high-velocity airflow to clean overhead areas. This ultra-powerful airflow effectively prevents the accumulation of combustible dust on overhead structures and provides better dust control for your grain processing facility. The technology behind these fans will automate your dust management, operating in the background without any extra thought from you or your employees.

Thermal-Current Control

Typical airflow involves warm air currents naturally rising and lifting dust to overhead structures, where it accumulates quickly. SonicAire’s industrial dust control fans prevent these naturally occurring upward thermal currents from holding dust in the air in the first place. Our fans create an air barrier below the overhead structures so the dust doesn’t rise above them and settle on top. When dust isn’t given free-reign in a facility the air quality will also inevitably improve.

With these unique and efficient approaches, our specialists design a customized plan, especially for your facility, to ensure that the dust accumulation in your facility is kept at a safe, minimal level.

SonicAire can mitigate the danger of combustible dust in your mill; reach out to speak to one of our specialists to get started. We’ll guide you through exactly how to make your workspace as safe as possible from dangerous buildup, while also saving you time and money from manual cleaning, insurance costs, and OSHA fines.

A Visible Difference

As they say, seeing is believing, and at SonicAire, we’re all too eager to share before and after photos of a facility just like yours.

Additional Resources

Learn more about how we helped companies like yours find solutions to their dust problems.

Complimentary Dust Management Plan with ROI Analysis

Our analysis will also show you the expected Return on Investment, including equipment investment, estimated annual savings and cumulative cashflow benefit.

Get started by contacting us today for your custom facility review, ROI analysis and fan technology proposal.

Feed, Grain, and Ag Industry Overview

Shaped by innovations in industrial processing, biotechnology, and logistical advances, the grain industry is rapidly adjusting to market trends and consumer preferences. It remains a major contributor to the U.S. economy and global markets. In its May 30, 2019, Grain Market Report, the International Grains Council (IGC), forecast total U.S. grains production in 2019-20 at 426.2 million tons.

With this production level, U.S. mills generate an incredible amount of grain for domestic and foreign markets. They also generate an incredible amount of dust.

These grains flow from 500,000 U.S. grain farms that generate a combined annual grain revenue of around $60 billion. Together, the agriculture, feed, and grain industries contributed $1.053 trillion to the United States GDP in 2017.

The major grains in this industry include Corn, Sorghum, Barley, Oats, Flour, Cereals, Fishmeal, & Spice.

Get Your Complimentary Dust Management Plan with ROI Analysis

Our analysis will also show you the expected Return on Investment, including equipment investment, estimated annual savings and cumulative cashflow benefit.

Get started by contacting us today for your custom facility review, ROI analysis and fan technology proposal.