Combustible Dust in the Paper Industry

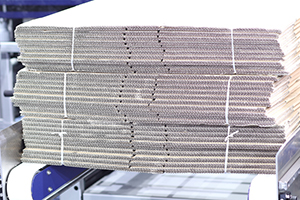

Packaging material. Printing paper. Personal care products. The paper industry produces a vast range of items in facilities across the country. What else does the industry produce every day? Combustible dust.

As manufacturers create various paper products, facilities generate combustible dust in the forms of pulp, wood, coal, ashes, resins and starch. When this combustible dust collects on surfaces and remains confined in a plant, it takes just one ignition source to initiate a potential disaster. Open flames, hot surfaces and electrostatic discharges are a few of the potential ignition sources that are present in paper manufacturing and conversion facilities.

When these conditions are right, combustible dust can create an explosion and/or fire which can injure employees and cripple the business. Prolonged exposure to paper dust can also cause additional health risks for employees, such as respiratory illness.

To mitigate these risks, paper industry professionals must properly manage the combustible dust in their facilities. Solutions have improved over the years, but not all are effective. Combustible Incident Reports from 2017-2018 show a total of 14 combustible dust incidents in the North American pulp and paper industry. Three of these incidents were explosions. Manual housekeeping isn’t getting the job done for paper manufacturers, and dust collection systems alone are not able to capture all the dust created. The industry needs a proactive solution that effectively protects paper manufacturers and paper converters from combustible dust events.

How SonicAire Can Help

How SonicAire Can Help

Offering precision dust-control technology, SonicAire is the ideal partner for paper facilities. Engineered as more than a clean-up solution, SonicAire’s proactive industrial dust control fans prevent combustible dust build-up and effectively mitigate the risk of disaster.

The SonicAire Solution

SonicAire proprietary technology combines two methods to control dust flow.

SonicAire fans use high-velocity airflow to clean overhead areas. The strength of this airflow effectively prevents the accumulation of combustible dust particles on overhead structures in the facility.

Typical airflow includes upward thermal currents which naturally lift and carry particles to overhead areas of facilities, where dust quickly accumulates and can become a fire hazard. SonicAire industrial dust control fans prevent these upward thermal currents from holding dust in the air.

SonicAire at Work

Put SonicAire to Work for You

With an engineered layout custom-designed for your plant, SonicAire fans will replace high-risk and costly manual cleaning measures, eliminate the need for housekeeping shut-downs and help maintain a clean, safe environment. Use the Learn More form above, at right to request more information or visit our Dust Solutions page to learn more about how SonicAire can help to solve your combustible dust challenges.