New Service – Free ROI Analysis

We’re here to help you tackle combustible dust in your facility. Contact our team for a complimentary facility review, ROI analysis, and fan technology proposal.

The free analysis will demonstrate:

- Estimated system investment

- Expected ROI

- Estimated annual savings

- Cumulative cashflow benefit

Contact SonicAire today to request your complimentary dust management plan with ROI analysis.

Owners of Any Overhead Dust Fans…

Upgrade Now for a $299 Per Fan Credit Toward Purchase

Upgrade any brand, any model of Overhead Dust Fans to the new SonicAire Pro, Extreme, or Specialty Series technology and receive a $299 per fan credit toward the purchase of a replacement fan. This is a limited time offer, which expires October 30, 2020.

- 1 & 2 hp motors

- Full 360° rotation

- Angular oscillation range between 120° and 35°

- Regular and compact models to suit every setting

Upgrade your fans to the latest models now and receive a $299 credit per fan. Offer expires October 30, 2020.

Download the promotional flier today.

Contact SonicAire today to take advantage of this limited time offer.

FAQs on Combustible Dust

Exactly what is combustible dust? And, more importantly, how could it affect your operations? Here’s what you need to know to keep your facility safe and compliant.

What is combustible dust?

OSHA defines combustible dust as “fine particles that present an explosion hazard when suspended in air under certain conditions.” Types of combustible dust include organic, wood, metal, plastic, rubber, textiles, and more.

When these particles accumulate on overhead areas, they pose a safety hazard due to potential fires and explosions. Even a small amount of dust creates risk. Per OSHA, as little as 1/32″ of dust—the thickness of a single paper clip—can have the capacity to explode.

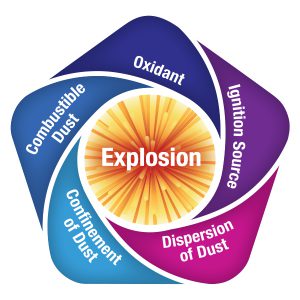

Five conditions must be present to cause a combustible dust event. This is referred to as the “Dust Explosion Pentagon.”

Learn more about how the dust explosion pentagon works.

Is my facility susceptible to dust explosions?

The fact is, any location where all five conditions of the dust explosion pentagon can be present may be at risk of combustible dust incidents. Does your facility process, cut, grind, polish, shape, mix, blast, crush, transport or otherwise handle products and materials that will generate dust? If so, your facility can be susceptible to dust explosions.

How can I prevent combustible dust events at my facility?

Appropriate housekeeping measures are key to reducing dust accumulation in overhead areas. This is either a manual process (scheduled downtime when your workers or contractors suit up and climb or use a lift to access and physically clean the ceiling area) or through the use of industrial dust control fans. Fans can be programmed to continuously clean overhead areas or work between shifts or after hours.

What else do I need to know about combustible dust control?

Is your facility compliant with current regulations? Are you familiar with the risk of primary and secondary explosions, and deflagration? Learn more about the risk of combustible dust events at your facility, how to maintain compliance with NFPA and OSHA regulations, and more.

What Do These 4 Companies Know that You Don’t?

This pellet manufacturer learned that SonicAire fans blow other solutions away:

“We’re amazed at how clean the overhead areas are staying,” says Galis. “There is practically zero dust in the rafters.” Learn more…

This plastics manufacturer realized they could save thousands each month on housekeeping:

Now, SonicAire fans work while the facility is in operation. Gray reports, “We run the fans 24/7, and they have kept the overhead areas constantly clean.” Learn more…

This linen service needed to meet industry standards, so it turned to SonicAire:

Buchbinder reports, “SonicAire fans really help us maintain that environment, making it a lot easier for my team to keep the plant clean and free of lint.” Learn more…

This fiberglass boat manufacturer discovered an effective way to mitigate risk:

Read the full stories in the SonicAire Knowledge Center to discover what else these manufacturers found, or visit our Success Stories page.

New Service – Free ROI Analysis

We’re here to help you tackle combustible dust in your facility. Contact our team for a complimentary facility review, ROI analysis, and fan technology proposal.

The free analysis will demonstrate:

- Estimated system investment

- Expected ROI

- Estimated annual savings

- Cumulative cashflow benefit

Contact SonicAire today to request your complimentary dust management plan with ROI analysis.

Owners of Any Overhead Dust Fans…

Upgrade Now for a $299 Per Fan Credit Toward Purchase

Upgrade any brand, any model of Overhead Dust Fans to the new SonicAire Pro, Extreme, or Specialty Series technology and receive a $299 per fan credit toward the purchase of a replacement fan. This is a limited time offer, which expires October 30, 2020.

- 1 & 2 hp motors

- Full 360° rotation

- Angular oscillation range between 120° and 35°

- Regular and compact models to suit every setting

Upgrade your fans to the latest models now and receive a $299 credit per fan. Offer expires October 30, 2020.

Download the promotional flier today.

Contact SonicAire today to take advantage of this limited time offer.

FAQs on Combustible Dust

Exactly what is combustible dust? And, more importantly, how could it affect your operations? Here’s what you need to know to keep your facility safe and compliant.

What is combustible dust?

OSHA defines combustible dust as “fine particles that present an explosion hazard when suspended in air under certain conditions.” Types of combustible dust include organic, wood, metal, plastic, rubber, textiles, and more.

When these particles accumulate on overhead areas, they pose a safety hazard due to potential fires and explosions. Even a small amount of dust creates risk. Per OSHA, as little as 1/32″ of dust—the thickness of a single paper clip—can have the capacity to explode.

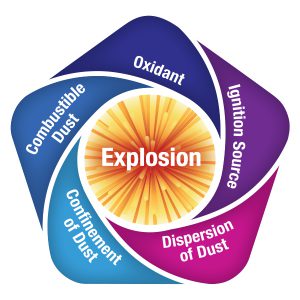

Five conditions must be present to cause a combustible dust event. This is referred to as the “Dust Explosion Pentagon.”

Learn more about how the dust explosion pentagon works.

Is my facility susceptible to dust explosions?

The fact is, any location where all five conditions of the dust explosion pentagon can be present may be at risk of combustible dust incidents. Does your facility process, cut, grind, polish, shape, mix, blast, crush, transport or otherwise handle products and materials that will generate dust? If so, your facility can be susceptible to dust explosions.

How can I prevent combustible dust events at my facility?

Appropriate housekeeping measures are key to reducing dust accumulation in overhead areas. This is either a manual process (scheduled downtime when your workers or contractors suit up and climb or use a lift to access and physically clean the ceiling area) or through the use of industrial dust control fans. Fans can be programmed to continuously clean overhead areas or work between shifts or after hours.

What else do I need to know about combustible dust control?

Is your facility compliant with current regulations? Are you familiar with the risk of primary and secondary explosions, and deflagration? Learn more about the risk of combustible dust events at your facility, how to maintain compliance with NFPA and OSHA regulations, and more.

What Do These 4 Companies Know that You Don’t?

This pellet manufacturer learned that SonicAire fans blow other solutions away:

“We’re amazed at how clean the overhead areas are staying,” says Galis. “There is practically zero dust in the rafters.” Learn more…

This plastics manufacturer realized they could save thousands each month on housekeeping:

Now, SonicAire fans work while the facility is in operation. Gray reports, “We run the fans 24/7, and they have kept the overhead areas constantly clean.” Learn more…

This linen service needed to meet industry standards, so it turned to SonicAire:

Buchbinder reports, “SonicAire fans really help us maintain that environment, making it a lot easier for my team to keep the plant clean and free of lint.” Learn more…

This fiberglass boat manufacturer discovered an effective way to mitigate risk:

Read the full stories in the SonicAire Knowledge Center to discover what else these manufacturers found, or visit our Success Stories page.