What is combustible dust, and how does it affect your operations? Discover what you need to know as we answer the most frequently asked questions about combustible dust.

What is combustible dust?

OSHA defines combustible dust as “fine particles that present an explosion hazard when suspended in air under certain conditions.” These particles come in a variety of shapes, sizes and compositions. Types of combustible dust include organic, wood, metal, plastic, rubber, textiles and more.

When these particles accumulate on overhead areas they pose a safety hazard due to potential fires and explosions. Even a small amount of dust creates risk. Per OSHA, as little as 1/32″ of dust—the thickness of a single paper clip—can have the capacity to explode.

How can dust explode?

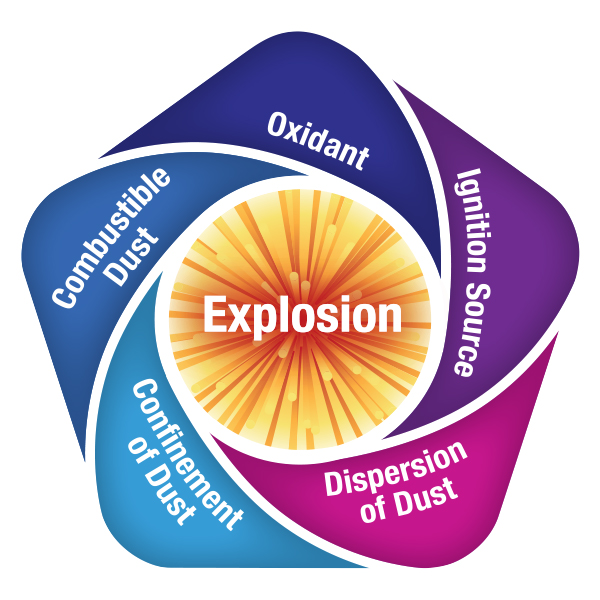

Five conditions must be present to cause a combustible dust event. This is referred to as the “Dust Explosion Pentagon.”

- Dust: An application that generates dust.

- Dispersion: Accumulated dust that has spread over the area to form a suspended dust cloud.

- Confinement: Interior conditions that trap the dust cloud.

- Oxidant: Oxygen in the surrounding air.

- Ignition source: This could be something as minor as static electricity or a spark from metal scraping metal.

Here’s how the Dust Explosion Pentagon works: As products are created or handled, the process inevitably creates dust (#1), which then travels on air currents and settles on various equipment and structural elements in the surroundings. In a confined area (#3), such as a manufacturing facility, the dust can also become suspended (#2) in the air (#4). Open flames, a spark from equipment, or even extreme heat can provide the ignition source (#5) to complete the pentagon.

When this happens, the suspended, contained dust can explode. This can ignite layers of dust that have accumulated in the facility, further spreading the fire.

What are primary and secondary combustible dust explosions?

As referred to in the previous question, when combustible dust ignites, it can cause more than one event. When the pentagon is complete, the first explosion occurs. This is referred to as the primary explosion.

This explosion may disturb or loosen other accumulated dust in the area. As this dust forms another cloud, it ignites as well. This explosion, referred to as a secondary dust explosion, can cause more destruction than the initial one.

These explosions and and subsequent fires can cause devastating structural damage, personal injury and loss of life. Between 2006 and 2017, combustible dust incidents in the U.S. resulted in 66 fatalities and 337 injuries, according to reports by the Chemical Safety and Hazard Investigation Board (CSB).

What is deflagration?

Deflagration is simply the heating of a material until it rapidly burns. It involves the release of heat by a burning substance, which ignites and spreads fire. A gas stove and the burning of gasoline in an automobile are common, safe examples of deflagration. During a combustible dust event, deflagration happens so quickly that it produces pressure that can cause explosions.

What settings are susceptible to dust explosions?

Any location where all five conditions of the dust explosion pentagon can be present may be at risk of combustible dust incidents. Facilities that process, cut, grind, polish, shape, mix, blast, crush, transport or otherwise handle products and materials will generate dust. The CSB has reported dust explosions in a wide variety of industries, including food, lumber, chemical, metal, rubber, plastics, electrical and equipment manufacturing. OSHA identifies over 130 sources of dust that create the potential for combustible dust explosions.

What regulations guide combustible dust safety and compliance?

For safe and legal operation, facilities must adhere to standards set by OSHA and the National Fire Protection Association (NFPA). Several Federal OSHA standards are mandatory, and many states have adopted OSHA-approved plans that adhere to these standards.

The standards set by the NFPA are created by experts in fire safety. While their recommendations are not legally binding, the NFPA standards are often used to create OSHA state and federal regulations. The most recent standard set by the NFPA is NFPA 652: Standard on the Fundamentals of Combustible Dust. This document includes requirements for the completion of dust hazard analyses (DHA) as well as hazard management steps for mitigation and prevention.

Failure to comply with OSHA standards can result in severe penalties. In 2017, OSHA wrote 319 citations related to combustible dust. Recent violations include a metal tank manufacturer that was fined $108,900 for dust accumulation and a milling facility that suffered a dust explosion resulting in $1.8 million in OSHA fines.

How can facility managers prevent combustible dust events?

Appropriate housekeeping measures are key to the prevention of combustible dust events. Facility managers can take proactive steps to minimize dust accumulation and mitigate risk.

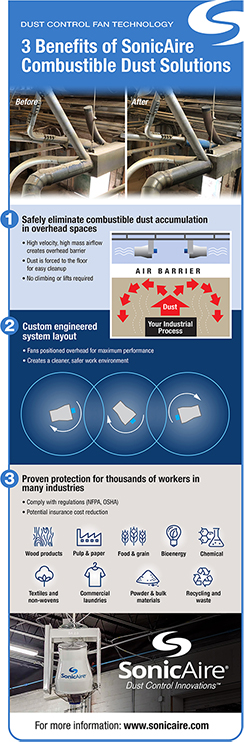

SonicAire industrial dust control fans are an ideal solution. These fans use BarrierAire™ technology to control dust accumulation in overhead areas. Using thermal-current control, SonicAire fans prevent upward flow that can hold dust in the air. The fans combine this control with high-velocity airflow to continuously clean overhead areas and prevent the accumulation of combustible dust on overhead structures.

The SonicAire Solution

The SonicAire team delivers engineered solutions for each facility that maximize results while minimizing cost. The outcome: safer, healthier and more efficient work environments.

To reduce combustible dust risk at your facility, contact the industry leaders at SonicAire for a custom solution and quote.