Unless you’re thoroughly informed about dust, you may think only a few types are combustible. Unfortunately, that’s not entirely true. Most dusts, even those that may seem harmless, are combustible. Even when the dust isn’t combustible, it’s often still flammable, posing a significant safety risk, as well. From everyday household items like flour and wood shavings to industrial materials like metal and plastic powders, dust risks are far too often underestimated.

The true challenge isn’t determining whether or not your dust is combustible but preventing the risk once you discover you have it. You can’t start the battle, though, until you’re sure what kind of dust you’re fighting.

So, let’s get into the how-to on identifying your dust type.

Types and Risks of Combustible Dust

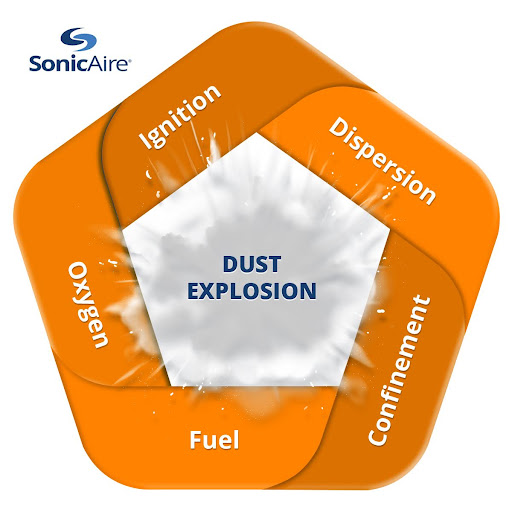

The explosion hazards of combustible dust are sometimes overlooked, yet they represent a significant risk in numerous industrial sectors. Recognizing the types of combustible dust in different industries and understanding the conditions under which these materials become explosive will improve your chances of preventing accidents.

Woodworking Industry and Combustible Dust

The woodworking industry generates highly combustible dust, particularly with engineered wood manufacturing and millwork. Fine wood particles released during cutting, sanding, or machining operations create severe fire hazards when airborne and after they settle on a surface.

Generated Dust Types

Sawdust is the primary combustible dust in those settings. When generated through processing, it is suspended in the air, creating an environment ideal for ignition.

Historical Incidents

A dust-related incident occurred in 2022 at the West Fraser Mill in Inverness, Scotland. A conveyor system explosion was triggered by accumulated wood dust igniting, causing substantial damage and injuring several workers.

Agriculture Industry’s Combustible Dust Sources

Agricultural processes contribute significantly to combustible dust generation. The handling, storage, and processing of grains produce large amounts of flammable particles.

Dust Generation From Grains

Grain dust, primarily from commodities like wheat, corn, and soybeans, presents severe risks in silos, grain elevators, and feed mills. These areas often have ignition sources like static electricity, mechanical sparks, hot work, and even lights. They create hazardous conditions for dust explosions when dust accumulates or is just present in the air like in CIID1 environments.

Incident Example

In 1998, the DeBruce Grain Elevator explosion in Kansas City resulted from poor housekeeping grain dust, tragically claiming lives and highlighting the importance of effective dust management strategies in agricultural settings.

Food Processing Combustible Dust

The food processing industry also faces unique threats from combustible dust from ingredients in baking mixes like flour, sugar, and spices.

Common Dust Types Produced

Flour and sugar dust are two prevalent forms of combustible dust encountered in bakeries and confectioneries. The milling, mixing, and conveying processes involved in production can release fine particles that pose significant risks if not properly managed.

Significant Incidents

One example of a food dust incident is the Imperial Sugar Company explosion in Georgia in 2008. Multiple fatalities and facility destruction occurred when sugar dust was allowed to build up and caused a combustible dust incident.

Chemical Manufacturing and Dust-related Risks

Chemical manufacturing involves diverse dust sources that present notable combustion risks, especially from powdered chemicals used in pharmaceuticals and pigments.

Types of Chemical Dusts

Many fine particulates in chemical plants can ignite under the right circumstances. Compounds from coal, rubber, sulfur, and even certain plastics are highly flammable, requiring careful handling.

Notable Accidents

A significant incident occurred at West Pharmaceutical Services in Kinston, NC, back in 2003, resulting from plastic dust ignition, killing six and injuring dozens more.

Metalworking Combustible Dust Challenges

The metalworking sector produces combustible dust, adding another layer of complexity to explosion hazards.

Sources of Metal Dust

Metalworking processes, including grinding and polishing, generate aluminum, magnesium, and iron dust, among others. These fine metallic particles are known to combust, especially in airborne concentrations.

Metal Dust Explosions

The Hoeganaes Corporation plant explosion in Tennessee in 2012 demonstrated the catastrophic potential of metal dust hazards. The ignition of powdered iron dust resulted in fatalities, underscoring the urgency of controlling dust levels in metal manufacturing environments.

Preventing Combustible Dust Events Through Expert Testing

With stringent regulations governing safety standards, facility operators must actively engage in combustible dust testing. The goal is as much to foster a culture of safety that protects employees and business continuity as it is to meet compliance requirements.

Dust Hazard Analysis

A Dust Hazard Analysis (DHA) is a comprehensive evaluation designed to identify, assess, and mitigate risks associated with combustible dust in industrial facilities. According to NFPA 652, the requirement to conduct a Dust Hazard Analysis (DHA) for existing facilities became mandatory by September 7, 2020; this applies retroactively to all facilities with combustible dust hazards, meaning they needed to complete a DHA by that date if they hadn’t already done so. OSHA’s new National Emphasis Program has already begun to bring DHAs into the focus of facilities with combustible dust.

To learn more about Dust Hazard Analysis and why you need one, check out our YAWA, What’s a DHA and Why Does it Matter? or our blog, The Complete Guide to Dust Hazard Analysis (DHA) for Manufacturing Facilities.

Key Components of a DHA

- Project Scope: The DHA begins with project details, including contact information for key personnel, scope, and revision history. This introductory section provides context and credibility for the analysis.

- Executive Summary: A high-level overview highlights key findings and recommendations. It often includes an introduction to combustible dust hazards, regulatory requirements (like OSHA and NFPA standards), and the risks posed to the facility.

- Facility Overview & Flammability Data: Detailed descriptions of the facility’s layout, processes, and materials handled are paired with flammability data. Metrics like maximum explosion pressure and minimum ignition energy help define the severity of potential hazards.

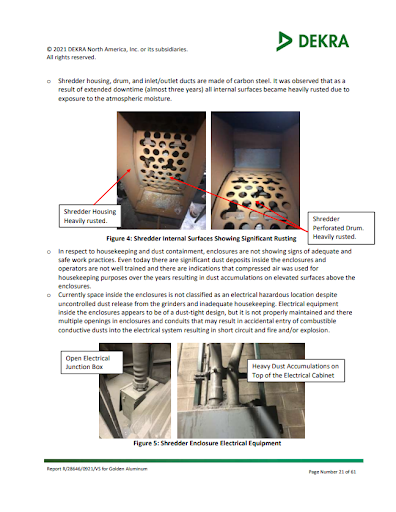

- Dust Hazard Analysis: This section dives into the core findings, detailing specific processes, potential hazard areas, and photographic evidence of issues. Recommendations for risk mitigation are tailored to each process.

- General Safety Recommendations: The DHA provides guidelines for controlling ignition sources, fire protection, hot work safety, housekeeping, and hazardous area classification. These address practical measures to prevent ignition and minimize risks.

- NFPA Equipment Requirements: The DHA outlines NFPA’s standards for equipment in combustible dust environments, focusing on explosion protection and isolation systems.

- Conclusions & Recommendations: The summary emphasizes key findings and a list of actionable recommendations so facility managers can efficiently implement changes to reduce risks and improve safety.

Following a DHA’s insights can proactively address your combustible dust hazards, align with regulatory standards, and foster a safer environment for workers and visitors. For more on DHAs, including examples and how to interpret them, check out our blog, The Complete Guide to Dust Hazard Analysis (DHA) for Manufacturing Facilities.

Comprehensive Testing Services

Dust testing powerhouses DEKRA and FIKE each provide an extensive suite of testing services that equip organizations with the tools necessary to manage combustible dust hazards effectively. These scientific evaluations provide crucial data to inform safety measures for plant managers.

Explore Ignition Sensitivity Tests

Ignition sensitivity tests form a fundamental part of their testing portfolios, determining the likelihood of ignition from various energy sources. Understanding these parameters is crucial to defining suitable protective measures tailored to each facility’s specific conditions.

The sensitivity of dust to ignition significantly impacts safety planning. The tests listed below yield vital information on dust behavior under varying thermal conditions.

Three Primary Measurements that Determine Combustibility

KST Value: The KST Value quantifies how fast the pressure increases during an explosion. This helps predict how much damage the potential explosion could cause (how big an event it would be).

Minimum Ignition Energy (MIE): Measures how easily dust is ignited and how much energy is needed to ignite it.

Minimum Explosive Concentration (MEC): How much dust must be present in the air to cause a combustion event.

The KST value doesn’t really determine any of the volatility of the dust, just how big an event would be if it occurred. You would use the MIE and the MEC to determine volatility. For example, a type of dust that requires only a small amount of energy and only a small volume to ignite is an incredibly volatile dust.

For more on this, check out our YAWA, which goes into the specifics: Why Is Grain Dust So Volatile?

Review Explosion Screening Tests

Explosion screening tests offer insight into whether a given substance is potentially explosive under certain conditions. Also called Go/No-Go classifications, these tests provide organizations with information on whether their dust materials pose immediate threats when subjected to ignition sources. Additionally, burning rate tests reveal how fast combustion propagates through particular powders, informing decision-makers of necessary response strategies and emergency protocols.

Understand Flammability Limits Assessments

Assessing flammability limits forms a crucial part of combustible dust testing. With this knowledge, organizations can implement better control measures to minimize exposure to hazardous atmospheres.

SonicAire: Your Shield Against Combustible Dust

While other dust control methods may offer temporary relief, SonicAire provides a proactive solution to eliminate combustible dust buildup. Traditional methods, like vacuuming, blow-downs, or using compressed air, are reactive measures that address the problem after dust has already accumulated. SonicAire’s innovative technology, on the other hand, prevents dust from settling in the first place, keeping you consistently compliant with OSHA regulations and safeguarding your facility from potential hazards.

By continuously agglomerating dust particles, SonicAire creates a clean and safe environment. Through agglomeration, the dust that would normally be in your hard-to-reach areas is now on the floor where it can easily be managed. This proactive approach minimizes the risk of fires and explosions, improves air quality, reduces maintenance costs, and enhances overall productivity.

How BarrierAire™ Technology Works

At SonicAire, we like to think we’ve perfected dust control with our innovative BarrierAire™ technology. By customizing fan layouts to suit your specific facility and dust type, we can guarantee compliance with industry standards.

- Disrupt Airflow: The fans create a constant air disturbance, preventing dust particles from settling above their airflow.

- Agglomeration: The agitated dust particles collide and stick together, forming larger, heavier particles.

- Settling: These larger particles are then pulled down by gravity, falling to the floor where they can be easily cleaned.

Don’t Compromise on Safety

Combustible dust is a silent but significant hazard across various industries, from woodworking and agriculture to chemical manufacturing and metalworking. The risks associated with combustible dust are not confined to one sector, nor are they limited to small-scale incidents. Historical disasters such as the Imperial Sugar explosion and the DeBruce Grain Elevator tragedy emphasize the devastating consequences of failing to recognize and mitigate these hazards.

However, the path to a safer workplace is clear. By understanding the types of combustible dust produced in your facility and assessing the conditions under which they become explosive, you can take proactive measures to prevent accidents. Tools like Dust Hazard Analysis (DHA), flammability limit assessments, and explosion screening tests provide invaluable data to guide safety strategies. Technologies like SonicAire’s BarrierAire™ system offer innovative solutions to minimize dust accumulation and ensure compliance with safety regulations.

A comprehensive approach to dust control, combining preventative measures, regular testing, and cutting-edge technology, is essential for safeguarding employees, protecting assets, and maintaining operational efficiency. By investing in effective dust management and fostering a culture of safety, industries can significantly reduce the risks of combustible dust, creating a safer future for everyone involved.

Unless you’re thoroughly informed about dust, you may think only a few types are combustible. Unfortunately, that’s not entirely true. Most dusts, even those that may seem harmless, are combustible. Even when the dust isn’t combustible, it’s often still flammable, posing a significant safety risk, as well. From everyday household items like flour and wood shavings to industrial materials like metal and plastic powders, dust risks are far too often underestimated.

The true challenge isn’t determining whether or not your dust is combustible but preventing the risk once you discover you have it. You can’t start the battle, though, until you’re sure what kind of dust you’re fighting.

So, let’s get into the how-to on identifying your dust type.

Types and Risks of Combustible Dust

The explosion hazards of combustible dust are sometimes overlooked, yet they represent a significant risk in numerous industrial sectors. Recognizing the types of combustible dust in different industries and understanding the conditions under which these materials become explosive will improve your chances of preventing accidents.

Woodworking Industry and Combustible Dust

The woodworking industry generates highly combustible dust, particularly with engineered wood manufacturing and millwork. Fine wood particles released during cutting, sanding, or machining operations create severe fire hazards when airborne and after they settle on a surface.

Sawdust is the primary combustible dust in those settings. When generated through processing, it is suspended in the air, creating an environment ideal for ignition.

2022 at the West Fraser Mill in Inverness, Scotland. A conveyor system explosion was triggered by accumulated wood dust igniting, causing substantial damage and injuring several workers.

Dust Generation From Grains

Dust Generation From Grains

Grain dust, primarily from commodities like wheat, corn, and soybeans, presents severe risks in silos, grain elevators, and feed mills. These areas often have ignition sources like static electricity, mechanical sparks, hot work, and even lights. They create hazardous conditions for dust explosions when dust accumulates or is just present in the air like in C2D1 environments.

DeBruce Grain Elevator explosion in Kansas City resulted from poor housekeeping grain dust, tragically claiming lives and highlighting the importance of effective dust management strategies in agricultural settings.

The food processing industry also faces unique threats from combustible dust from ingredients in baking mixes like flour, sugar, and spices.

Significant Incidents

One example of a food dust incident is the Imperial Sugar Company explosion in Georgia in 2008. Sugar dust produced by the company combusted, resulting in multiple fatalities and facility destruction.

Types of Chemical Dusts

Many fine particulates in chemical plants can ignite under the right circumstances. Compounds from coal, rubber, sulfur, and even certain plastics are highly flammable, requiring careful handling.

West Pharmaceutical Services in Kinston, NC, back in 2003, resulting from plastic dust ignition, killing six and injuring dozens more.

Sources of Metal Dust

Metalworking processes, including grinding and polishing, generate aluminum, magnesium, and iron dust, among others. These fine metallic particles are known to combust, especially in airborne concentrations.

Hoeganaes Corporation plant explosion in Tennessee in 2012 demonstrated the catastrophic potential of metal dust hazards. The ignition of powdered iron dust resulted in fatalities, underscoring the urgency of controlling dust levels in metal manufacturing environments.

Preventing Combustible Dust Events Through Expert Testing

With stringent regulations governing safety standards, facility operators must actively engage in combustible dust testing. The goal is as much to foster a culture of safety that protects employees and business continuity as it is to meet compliance requirements.

National Emphasis Program has already begun to bring DHAs into the focus of facilities with combustible dust.

To learn more about Dust Hazard Analysis and why you need one, check out our YAWA, What’s a DHA and Why Does it Matter? or our blog, The Complete Guide to Dust Hazard Analysis (DHA) for Manufacturing Facilities.

Project Scope:

Project Scope:

The DHA begins with project details, including contact information for key personnel, scope, and revision history. This introductory section provides context and credibility for the analysis.- Executive Summary:

A high-level overview highlights key findings and recommendations. It often includes an introduction to combustible dust hazards, regulatory requirements (like OSHA and NFPA standards), and the risks posed to the facility.

- Facility Overview & Flammability Data:

Detailed descriptions of the facility’s layout, processes, and materials handled are paired with flammability data. Metrics like maximum explosion pressure and minimum ignition energy help define the severity of potential hazards.

- Dust Hazard Analysis:

This section dives into the core findings, detailing specific processes, potential hazard areas, and photographic evidence of issues. Recommendations for risk mitigation are tailored to each process.

- General Safety Recommendations:

The DHA provides guidelines for controlling ignition sources, fire protection, hot work safety, housekeeping, and hazardous area classification. These address practical measures to prevent ignition and minimize risks.

- NFPA Equipment Requirements:

The DHA outlines NFPA’s standards for equipment in combustible dust environments, focusing on explosion protection and isolation systems.

- Conclusions & Recommendations:

The summary emphasizes key findings and a list of actionable recommendations so facility managers can efficiently implement changes to reduce risks and improve safety.

Following a DHA’s insights can proactively address your combustible dust hazards, align with regulatory standards, and foster a safer environment for workers and visitors. For more on DHAs, including examples and how to interpret them, check out our blog, The Complete Guide to Dust Hazard Analysis (DHA) for Manufacturing Facilities.

Project Scope:

The DHA begins with project details, including contact information for key personnel, scope, and revision history. This introductory section provides context and credibility for the analysis.- Executive Summary:

A high-level overview highlights key findings and recommendations. It often includes an introduction to combustible dust hazards, regulatory requirements (like OSHA and NFPA standards), and the risks posed to the facility. - Facility Overview & Flammability Data:

Detailed descriptions of the facility’s layout, processes, and materials handled are paired with flammability data. Metrics like maximum explosion pressure and minimum ignition energy help define the severity of potential hazards. - Dust Hazard Analysis:

This section dives into the core findings, detailing specific processes, potential hazard areas, and photographic evidence of issues. Recommendations for risk mitigation are tailored to each process. - General Safety Recommendations:

The DHA provides guidelines for controlling ignition sources, fire protection, hot work safety, housekeeping, and hazardous area classification. These address practical measures to prevent ignition and minimize risks. - NFPA Equipment Requirements:

The DHA outlines NFPA’s standards for equipment in combustible dust environments, focusing on explosion protection and isolation systems. - Conclusions & Recommendations:

The summary emphasizes key findings and a list of actionable recommendations so facility managers can efficiently implement changes to reduce risks and improve safety.

Following a DHA’s insights can proactively address your combustible dust hazards, align with regulatory standards, and foster a safer environment for workers and visitors. For more on DHAs, including examples and how to interpret them, check out our blog, The Complete Guide to Dust Hazard Analysis (DHA) for Manufacturing Facilities.

Comprehensive Testing Services

Dust testing powerhouses DEKRA and FIKE each provide an extensive suite of testing services that equip organizations with the tools necessary to manage combustible dust hazards effectively. These scientific evaluations provide crucial data to inform safety measures for plant managers.

Explore Ignition Sensitivity Tests

Ignition sensitivity tests form a fundamental part of their testing portfolios, determining the likelihood of ignition from various energy sources. Understanding these parameters is crucial to defining suitable protective measures tailored to each facility’s specific conditions.

The sensitivity of dust to ignition significantly impacts safety planning. These tests yield vital information on dust behavior under varying thermal conditions.

Review Explosion Screening Tests

Explosion screening tests offer insight into whether a given substance is potentially explosive under certain conditions. Also called Go/No-Go classifications, these tests provide organizations with information on whether their dust materials pose immediate threats when subjected to ignition sources. Additionally, burning rate tests reveal how fast combustion propagates through particular powders, informing decision-makers of necessary response strategies and emergency protocols.

Understand Flammability Limits Assessments

Assessing flammability limits forms a crucial part of combustible dust testing. With this knowledge, organizations can implement better control measures to minimize exposure to hazardous atmospheres.

SonicAire: Your Shield Against Combustible Dust

While other dust control methods may offer temporary relief, SonicAire provides a proactive solution to eliminate combustible dust buildup. Traditional methods, like vacuuming, blow-downs, or using compressed air, are reactive measures that address the problem after dust has already accumulated. SonicAire’s innovative technology, on the other hand, prevents dust from settling in the first place, keeping you consistently compliant with OSHA regulations and safeguarding your facility from potential hazards.

By continuously agglomerating dust particles, SonicAire creates a clean and safe environment. Through agglomeration, the dust that would normally be in your hard-to-reach areas is now on the floor where it can easily be managed. This proactive approach minimizes the risk of fires and explosions, improves air quality, reduces maintenance costs, and enhances overall productivity.

How BarrierAire™ Technology Works

At SonicAire, we like to think we’ve perfected dust control with our innovative BarrierAire™ technology. By customizing fan layouts to suit your specific facility and dust type, we can guarantee compliance with industry standards.

- Disrupt Airflow: The fans create a constant air disturbance, preventing dust particles from settling above their airflow.

- Agglomeration: The agitated dust particles collide and stick together, forming larger, heavier particles.

- Settling: These larger particles are then pulled down by gravity, falling to the floor where they can be easily cleaned.

Don’t Compromise on Safety

Protect your workers and your business with SonicAire’s advanced dust control solutions. Contact us today to learn more about how our CIID1-certified fans can transform your facility.

GET YOUR FREE GUIDE:

The Real Cost of Fugitive Dust in Hard-to-Reach Spaces

What You Can’t See Can Hurt You

To help protect your workplace, we’ve compiled the following resource, The Real Cost of Fugitive Dust in Hard-to-Reach Spaces: What You Can’t See Can Hurt You. In it, we identify seven ways fugitive dust is likely impacting your facility and its profitability.

These costs go beyond housekeeping and explain why you should be preventing dust buildup to protect the bottom line, not just to stay in compliance.